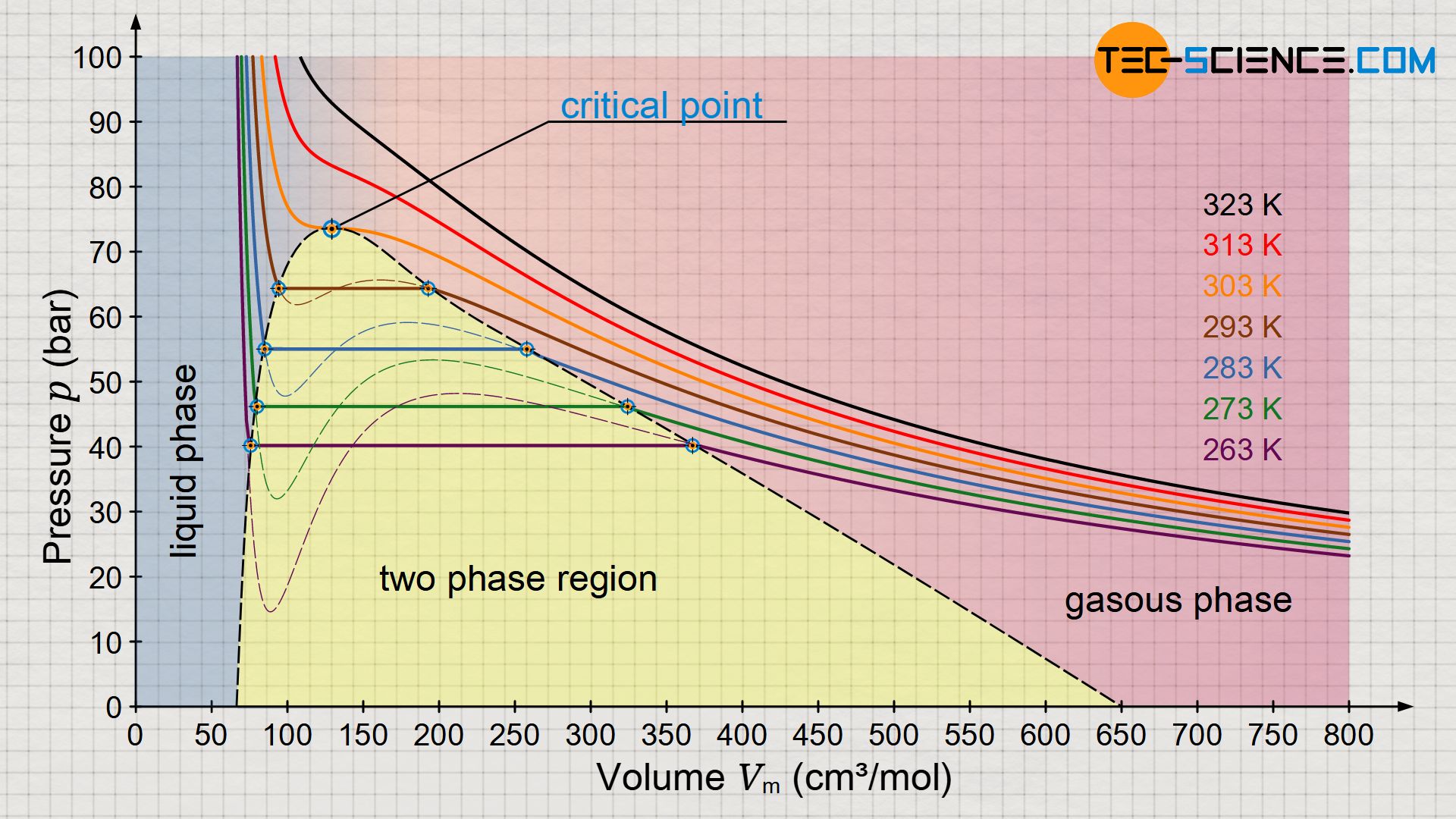

Physicochemical properties of slag and molten metal directly affect the surface and interfacial properties in refining process of molten metal. Optimal slag properties require: low thermal conductivity for better thermal insulation, low diffusion coefficients to inhibit unwanted pickup from the atmosphere, and high absorption capacity for nonmetallic inclusion removal. Slag as a mixture of oxide has specific properties of melting behavior, viscosity, and surface tension, among others.

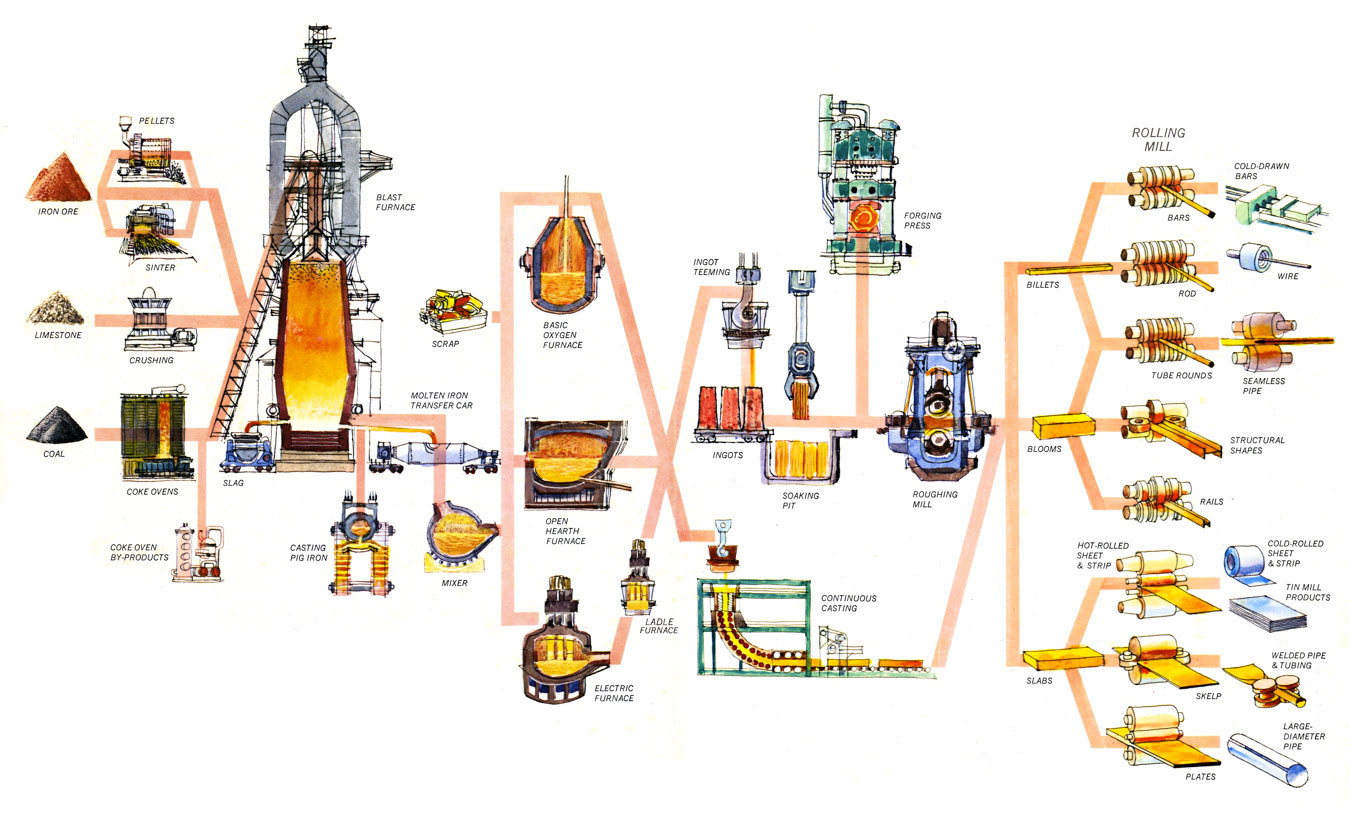

Slag in ironmaking and steelmaking processes has several metallurgical functions such as preventing contamination by atmosphere, providing thermal insulation, and removing impurities in the liquid metal. Efforts are on for economic use of all types of steel plant wastes, such as slag, dust, and flue gases. The most recent thrust is on more integrated green manufacturing and more intensive waste recycling for sustainable development. Developed countries are now laying tremendous emphasis on: (a) reduction in energy consumption per ton of steel produced and (b) sustainable environmental management. Safe disposal of slag and elimination of atmospheric pollution by waste gases are now a matter of serious concern in all steel producing countries. Steel production necessarily involves production of millions of tons of slag as well as waste gases containing harmful constituents such as carbon dioxide, dioxin, and furans. Energy consumption per ton of steel production is often considered a benchmark of operational efficiency. In modern steel plants, the emphasis is placed simultaneously on quantity and quality. Different experimental tests applied in slag characterization are also detailed. This chapter deals with the measurement and modeling of thermochemical properties of slags, thermophysical properties, and interproperty correlations. In this sense, understanding the properties of slags is a prerequisite to apply them in different functions. Blast furnace crystallized slags are used in cement production, in different percentages. It is known that cement concrete is one of the most common building materials.

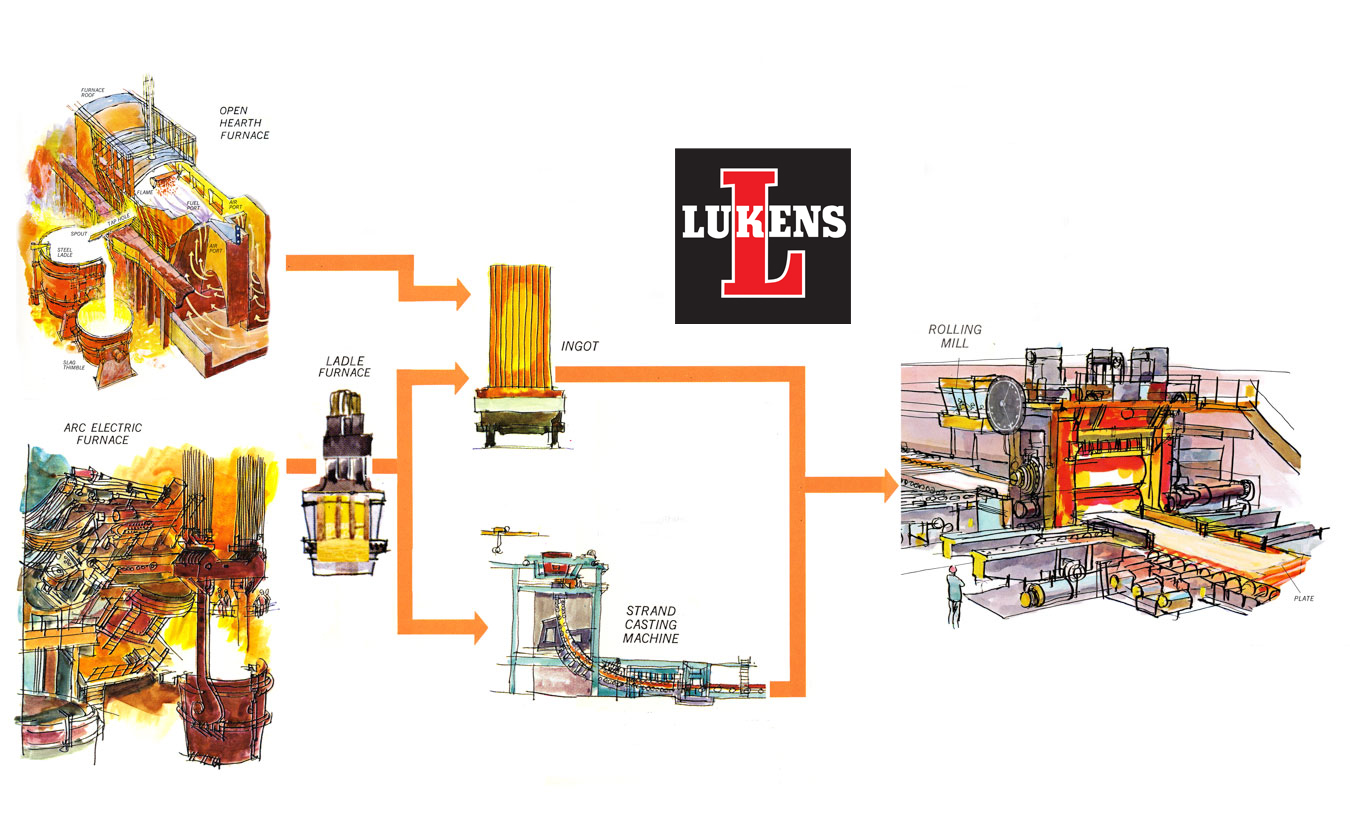

Also, EAF slags are commonly used to avoid refractory wear and decrease energy consumption. BOF-converter slags are also applied in buildup, foaming, or slag splashing practices carried out to prolong the lifespan of refractory lining. Steelmaking slag added into ladle slags makes it possible to minimize slag line wear. Metallurgical slags are considered secondary raw materials and are used or added during the process to improve steelmaking practice. In this chapter, techniques for the treatment and recycling of metallurgical slags are described. Steelmaking plants continuously strive to reduce the environmental load in the steelmaking process, resulting in the recycling of energy, water, and other byproducts.

0 kommentar(er)

0 kommentar(er)